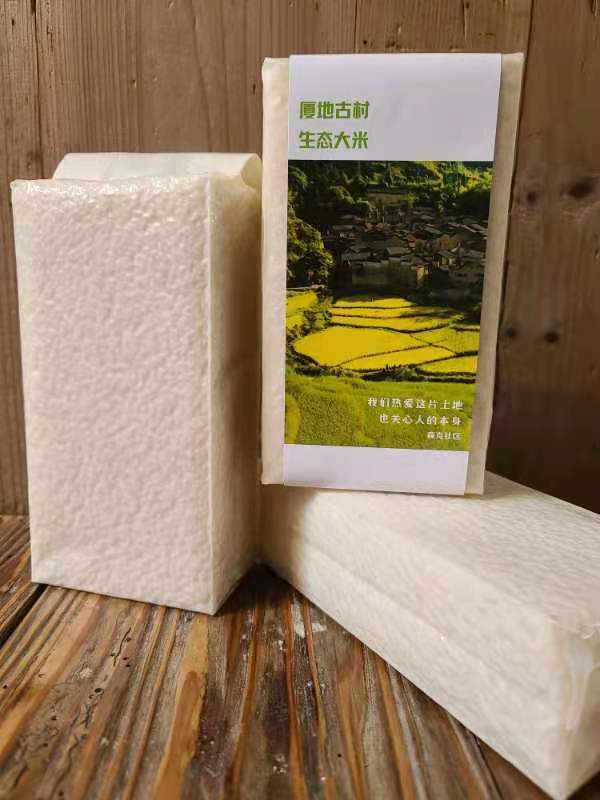

Vacuum packaging has many advantages. According to the literature, in Hong Kong and Southeast Asia, traditional methods of storing rice may have insects or mildew in 2/3 months, while vacuum packaging can last for at least one year, and up to two years for the elderly. . Another example is that under normal temperature conditions, the shelf life of fresh pork and beef is only 2/3 days, and it can reach 6/10 days after vacuum packaging. Most foods can be vacuum-filled packaging.

The main purpose is to prevent the proliferation of harmful microorganisms and extend the shelf life of food. Because the sealing temperature of vacuum packaging is high enough, most harmful microorganisms need water and oxygen to multiply. Vacuum packaging can isolate these two, so that the microorganisms in the food cannot multiply, thus The vacuum packaging machine for extending the shelf life of food will automatically seal the bag immediately after it has been pumped into a low vacuum. Due to the high vacuum in the bag, there is very little residual air, which can inhibit the growth of bacteria and other microorganisms. For some soft items, the volume can be reduced after vacuum packaging. So that the packaged items can achieve the characteristics of “four preventions, two provinces, and one quality guarantee”: that is, moisture proof, mildew proof, pollution proof, oxidation proof, volume saving, freight saving, and storage period prolonged.

The vacuum packaging machine is suitable for various plastic composite film bags or aluminum foil composite film bags, such as polyester/polyethylene, nylon/polyethylene, polypropylene/polyethylene, polyester/aluminum foil/polyethylene, nylon/aluminum foil/polyethylene, etc. Composite materials, for various solid, powder-like objects, liquids, solid-liquid mixtures, such as various raw and cooked foods, fruits, native products, medicinal materials, chemicals, precision instruments, clothing, hardware products, electronic components, military products, etc. Vacuum packaging. In the food industry, vacuum-packaged food is very common, various cooked products such as: chicken legs, ham, sausages, etc.; pickled products such as various pickles, various soy products, preserved fruits and other foods that need to be kept fresh are increasing. Vacuum packaging is used locally, and vacuum-packaged food has a long shelf life, which greatly extends the shelf life of the food.

However, it has always been difficult to achieve vacuum packaging bags with fully degradable materials because of the characteristics of fully degradable materials. The fully biodegradable products use corn starch, tapioca starch and plant fiber as the main raw materials, so the barrier performance of its materials is far better than that of non-degradable materials. Use plastic materials such as PET. However, Guangzhou Oemy Environmental Friendly Packaging has been committed to researching how to improve the barrier properties of fully degradable packaging bags, so that it can vacuumize and extend the shelf life of food. Through two years of research and improvement of fully degradable materials, it has greatly improved its barrier properties and realized the function of vacuuming. If you need a fully degradable composite packaging bag with high barrier properties, please contact us. www.oempackagingbag.com

Post time: Nov-16-2021