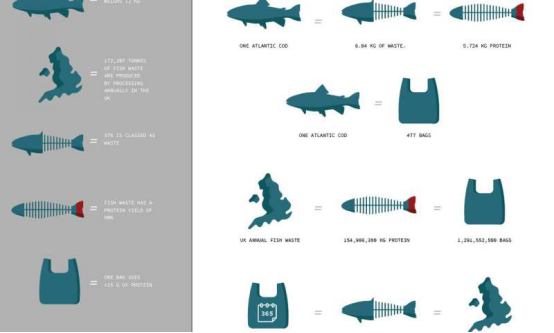

24-year-old Lucy invents biodegradable plastic made from fish waste (skins, scales). According to Lucy, only one cod can make 1,400 Marina Tex plastic bags, which can be broken down in fifteen trash in 4-6 weeks

This biodegradable bioplastic is made from a combination of wasted product from the fishing industry , and red algae. Unlike some other bioplastics which needs kind of , special infrastructure and higher temperatures.This material will biodegrade in kind of lower temperatures,which can be achieved in , kind of m home compost bins.It was created by University of Sussex Design graduate, Lucy Hughes.Her ideas are driven by Her belief that waste has a real value.So she’s developed a new bioplastic from what would have been thrown away,Because it’s using a waste material rather than a virgin material, you get that material at a much lower cost or sometimes, you know, free。And it’s roughly the same as an LDP plastic bag

Both biodegradable and cost effective, so what’s next for Lucy and Marina Tex?

“I’m kind of dedicating the next year to sort of work on grants and getting funding for it. But I do think a bit more R&D needs to go into it .So I want to be able to , you know like , get the material to its best qualities.” Lucy said

For Lucy’s invention, it was a good news for the world environment. Bio-degradable materials are just emerging, which is necessary for environmental protection. Although the price of most biodegradable materials still cannot impact the low cost of traditional plastic bags, such as PE, PET, ABS, etc., “white pollution” is still ongoing. But now the world environment is getting worse and worse, we even more urgently need a variety of fully degradable materials to replace traditional petroleum plastics.

OEMY Environmentally Friendly Packaging Company is committed to research and development, production and sales of fully degradable composite packaging bags. This fully degradable composite packaging bag is currently not as low in cost as traditional plastic packaging bags. This is because the fully degradable raw materials have risen in recent years and have been put into production and application. Compared with the traditional plastic raw materials that have been developed for hundreds of years, the production technology cannot achieve low cost. The price of fully biodegradable raw materials for biological starch is currently double that of traditional plastics PE, ABS, and PET.

However, in order to vigorously promote the fully degradable composite packaging bag, the OEMY company compresses the profit in the bag making process and allows some of the profit to our customers, which is also beneficial to the customer’s cost control and environmental protection.

Oemy Environmental Friendly Packaging Co., Limited.

Https://www.oempackagingbag.com/

Email: admin@oempackagingbag.com

Tel : 0086 13711875799

Post time: Dec-05-2019